Smaller, lighter and easier to use

The digital transformation of industry requires further development of existing cabling components, as conventional cabling concepts are too complex for many industrial applications and are unable to meet the new requirements, such as those in terms of space requirements. For the first time, Ethernet-based communication has been made possible from the sensor to the cloud with Single Pair Ethernet (SPE) technology. Likewise, SPE can be used across applications with a range of up to 1,000m and transmission speeds of up to 1GBit/s. With Power over Data Lines (PoDL), data and energy can be transferred simultaneously over just one wire. This simplifies installation compared to four-pair cabling solutions and significantly reduces both space and weight.

Single Pair Ethernet is ideal for Industry 4.0 applications such as building, factory and process automation. The big advantage is that as Single Pair Ethernet is environment-neutral, field devices, sensors and actuators can easily be integrated into an existing Ethernet environment. No additional gateways or interfaces are necessary. Single Pair Ethernet is more consistent, more efficient and more affordable than fieldbus systems.

Miniaturisation

The SPE connector acc. to IEC 63171-2 is currently the most compact mating face on the market and saves up to 50% space compared to RJ45 interfaces. Due to a vertical arrangement, the packing density can be doubled. In addition, the mating face can be optimally integrated into a standard M8 housing due to its compact design and it is the perfect solution for industrial applications, especially sensor technology.

Simplicity

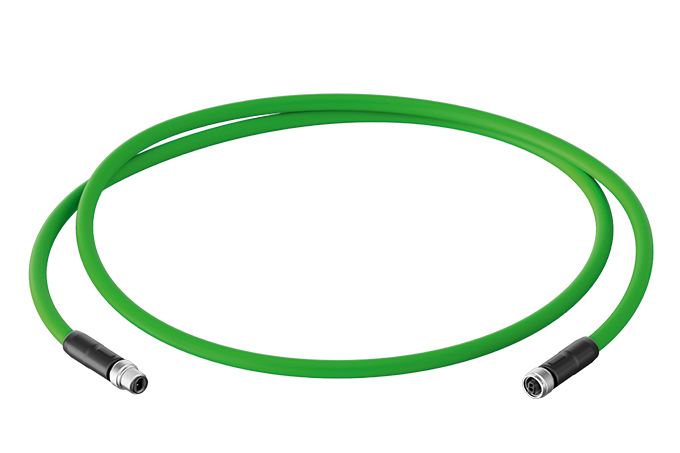

Our SPE connectors can be used across applications. The IP20 and IP67 mating faces can be combined as required and always fit together perfectly. The reduction to just one wire pair and the associated simple and standardised design significantly reduce size, weight and installation effort.

Future-proof

For the first time, Single Pair Ethernet technology makes standardised Ethernet-based communication possible across all levels, from the sensor to the cloud. This allows a consistent communication without extensive programming or the use of gateways. The result: considerable time and cost savings in the entire cabling system. As a key overarching technology for Industry 4.0 and IIoT applications, a wide range of industrial applications will be based on Single Pair Ethernet in future.

Performance

The origins of Single Pair Ethernet technology lie in the automotive industry, where it was originally developed to realise an efficient infrastructure that could deliver outstanding performance with as little cabling as possible. The expectations for industrial applications are similar, as SPE connectors are exceptionally robust and vibration-proof. They are not sensitive to electromagnetic influences and have been designed to meet the strict requirements of industrial applications. The transfer rates are even sufficient for challenging sensor components and reach up to 10 Mbit/s with a cable length of 1,000 m or 1 Gbit/s with a cable length of 40 m.

Designed for the highest requirements

As the process of automation progresses, a growing number of sensors and actuators are being used in all areas of manufacturing – which have to have reliable connections to cloud systems. With Single Pair Ethernet, field devices, sensors and actuators can easily be integrated into an existing Ethernet environment. No additional gateways or interfaces are necessary. Unlike fieldbus protocols, Ethernet can be implemented at all automation levels. It is more consistent, more efficient and more affordable than fieldbus systems. Additionally, the reduction to just one pair of wires makes it simpler to connect sensors in machines or systems and reduces the amount of installation work for the user.

Connector face | 63171-5 |

Number of poles | 2 |

Connection | Crimp |

Category | Cat. B (ISO/IEC 63171) |

Coupling damping | ≤ 600MHz |

Protection class | IP67 |

Temperature range | -40°C to +85°C |

Pollution degree | 2 |

PoDL | Acc. to IEEE 802.3bu |

Designed for the tasks of tomorrow

Intelligent buildings are more efficient, more secure and more comfortable. With the Internet Protocol, LED lights, switches, sensors, thermostats or window blind motors can connect to the building management system via the local data network and the cloud. This means that existing fieldbus systems are dethroned by continuous Ethernet cabling, eliminating the need for application-specific fieldbus systems as well as gateways, complex interfaces and various different protocols. This simplifies installation, maintenance and network management. Additionally, a high connection density can be achieved with the IP20 connector face and a large number of devices can be connected to the network.

The IEC 63171-2-compliant connector face is currently the most compact connector system. It is up to 50% more compact than RJ45 interfaces. This saves significant space on the circuit board for device manufacturers, paving the way for them to achieve a higher packing factor and build smaller devices. This reduces the delivery costs when devices are built and is an effective way to save space in the switchboard.

- The two-piece connector is easy to assemble

- Clear colour coding to avoid cabling errors

- Suitable for all conventional SPE cables

- Proven and established IDC technology

- Industry-standard plugs and jacks with metal snap-in hooks

- Well-known standard RJ45 locking mechanism